by chris

Share

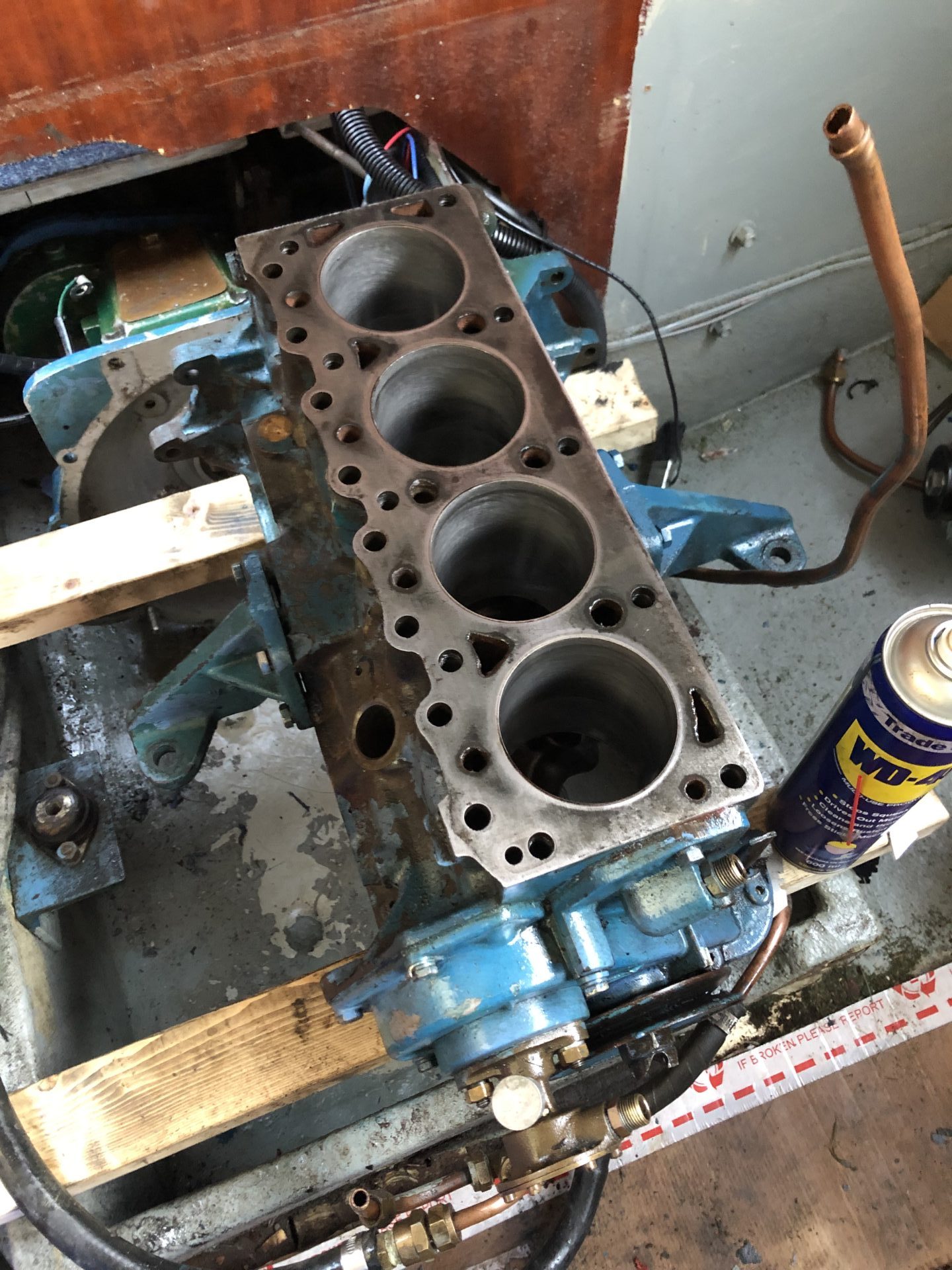

Having dis-assembled the engine and hopefully identified the issue, it’s time for the clean-up and preparation for the next step of my mission.

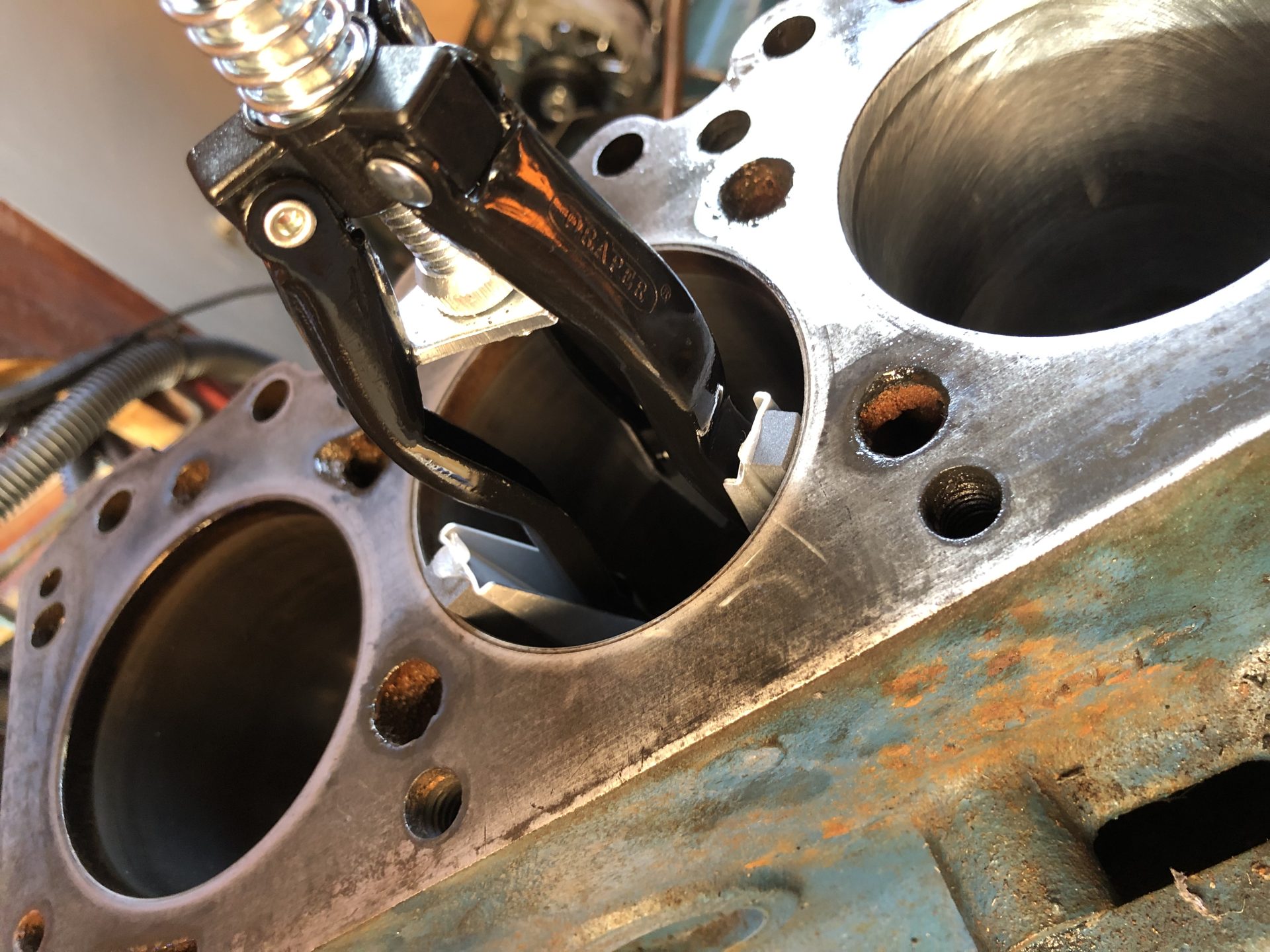

Although the bores were highly glazed with no sign of honing or crosshatching, they appeared to be in reasonable condition and serviceable after honing myself. The piston rings were moving freely, so that wasn’t the main issue. What did become clear was the play in the valves and signs of burning some oil through the exhaust valve of cylinder 2.

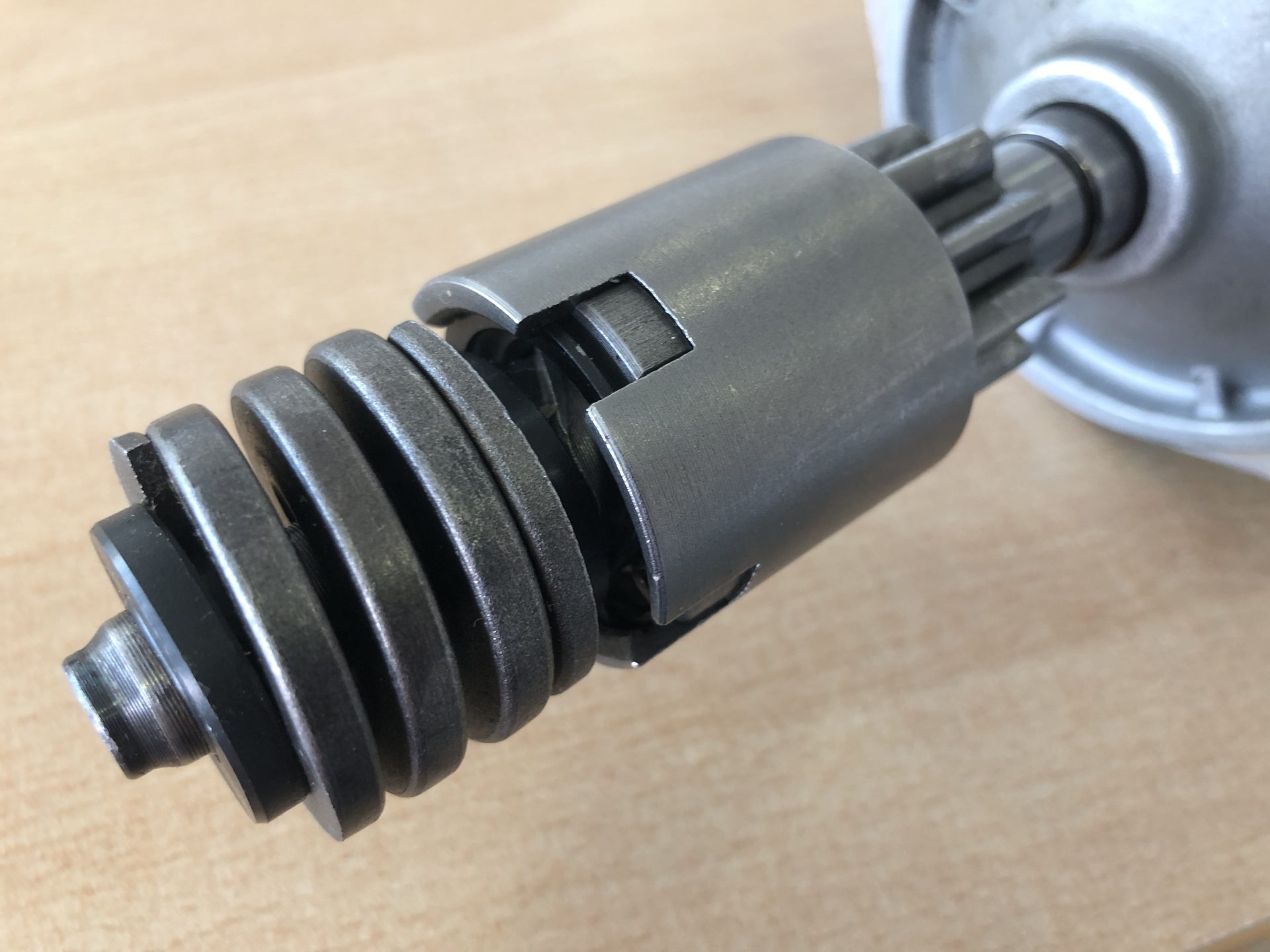

To this end, the cylinder head has gone to a classic Ford engine expert called Scholar Engineering to be crack tested with new hardened valve seats going in (to run unleaded fuel), new valve guide inserts and probably new valves. The head will be cleaned and have it’s gasket surfaces prepared for re-assembly along with the valves being lapped in.

In the mean time I’ll re-paint the engine bilge area with Danboline and clean up the remaining parts for re-assembly.

As I have no effective means of flushing water-based degreaser in an environmentally sound way, I’ve been using a WD-40 Degreasing product which seems to be doing a great job and then following up with a light misting of traditional WD 40 to prevent corrosion before re-assembling the engine.