by chris

Share

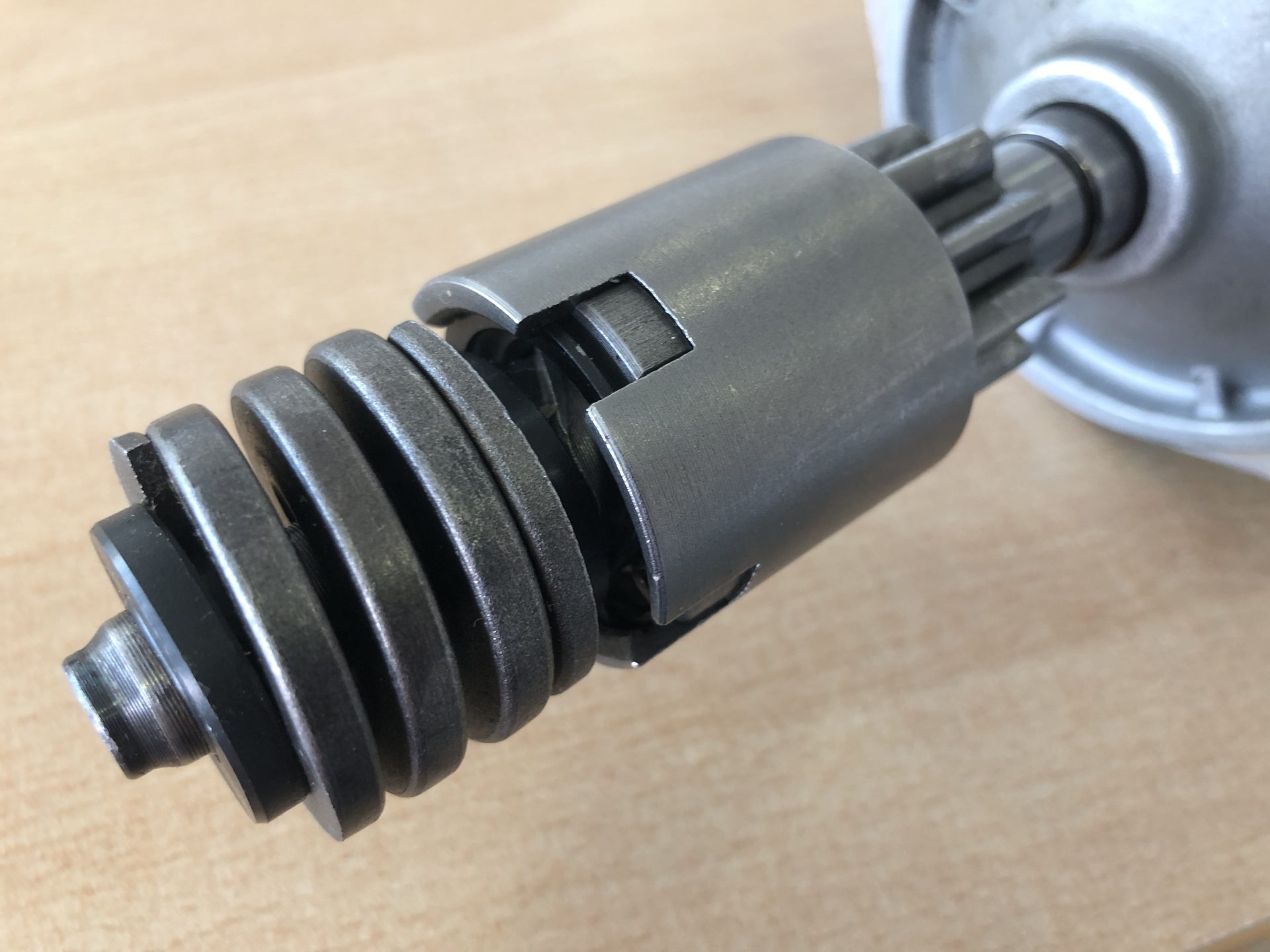

It was supposed to be a fairly simple job, having removed my J-type gearbox to deal with an on-going stub-shaft issue, I thought it would be as well to replace the well worn starter ring gear on my flywheel and also the starter motor as the bendix was becoming quite sloppy and damaged with a new starter not costing the earth.

Youtube (and my mechanic) suggested that swapping out a ring gear was pretty straightforward, a matter of blowtorching the ring to get it hot to facilitate removal and then placing the flywheel in a freezer and the ring gear in a very hot oven and then dropping it on. I had no such luck !

I couldn’t get the ring gear hot enough, quickly enough to remove it so had to resort to drilling and cold chiselling it off. This meant that I wouldn’t simply be able to reverse it if needed. I only had a fridge and a BBQ to fit the new ring but there wasn’t sufficient expansion in the ring for it to drop all the way home past a lip on the flywheel outer edge. I thought I’d ask a neighbour with an oxy torch to give it some next level heat but this also failed and warped the ring to boot. It rendered the ring useless and so I had to order another one.

Taking this to Martin (my mechanic) with a deep freeze, hot oven and experience, an attempt was made to fit the second ring gear but this failed too. The lip on the flywheel was causing the problem so the flywheel was taken to a local machine shop to have the lip removed. The third attempt to fit a ring gear was tight, but successful. By now over half my annual holiday had gone with my family getting twitchy.

With a ‘new’ second hand stub shaft, a new starter and ring gear, new engine mounts and a newly painted bilge (small bonus of having to wait for parts), it should have been a matter of bolting everything together. Not a chance !

Trying to get the run-out (alignment) of the stubshaft within the 0.002″ tolerance was impossible. The only point of accurate alignment is an off-centre dowel between the crankshaft flange and flywheel. Even this was sloppy and having spent over 6 hours attempting alignment with all the tricks in the book including the paper trick, the stub shaft was mounted a little out of tolerance just to allow us a couple of days out on the water rather than completely abandoning our summer holiday thanks to Martin jumping in, spanners ablaze and saving the day where I was prepared to walk away.

At this point, the whole flywheel and stubshaft assembly will be going back to the machine shop to be set true using a custom made locating collar between the crankshaft flange and flywheel to provide half a chance of alignment. I love my Freeman, but in this engineering aspect, ‘John’ should have had a little talking to !

I’ve yet to see the result of machining up a locating collar, so will post the result next time.