by chris

Share

This year, 2022, gave us our first opportunity to run the engine for any length of time. We motored for up to six hours daily at around the 1400rpm mark when cruising and the engine ran nice and smoothly however there were problems.

The first I noticed, even before going for a longer trip, was the amount of thin, whispy smoke coming from the valve cover filler cap. I was initially concerned as I noticed it when the base of the seat was removed in the spring. After a few enquiries, it became clear the the GRP moulding in the seat was a means of encouraging ‘blow-by’ fumes to be ingested back into the engine via the carburettor intake. This put my mind slightly at rest until in the summer I realised there was really quite a bit of smoke and the GRP moulding was beginning to be stained an orange brown.

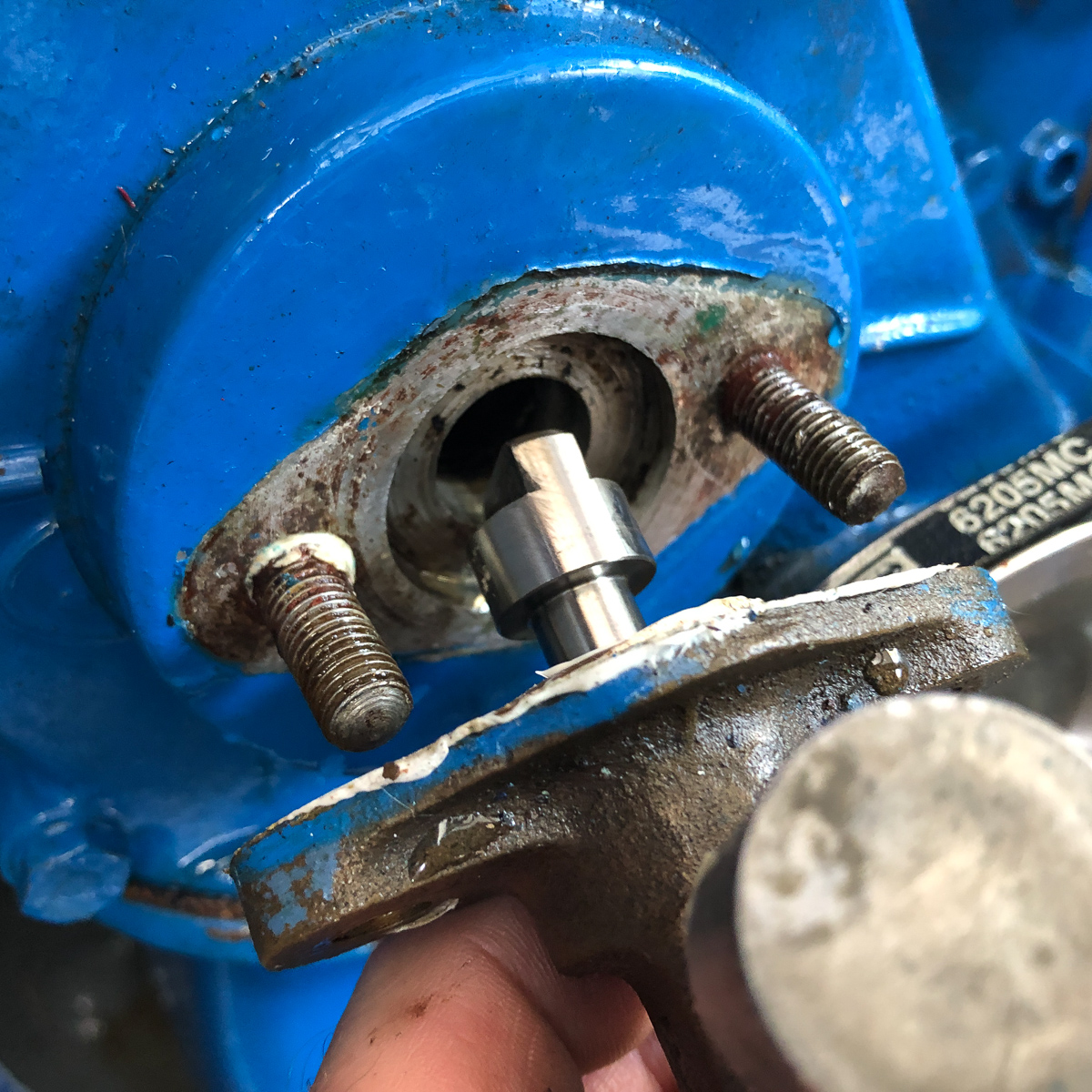

The second issue was more messy. I was losing oil into the bilges at a rate of perhaps a mug every 4 hours or so. It really wasn’t clear where it was coming from given that the sump is an odd shape and the engine compartment small so as to not be able to see. With some bloody mindedness, I discovered oil leaking from behind the front engine pulley and potentially also from the back of the engine.

Following a discussion with a seasoned Ford expert, it was clear both my front and rear crankshaft oil seals had given up. They were originally known to leak after a couple of years giving you a minor drip however the oil seals in my Freeman could easily have been the originals from 1968 !

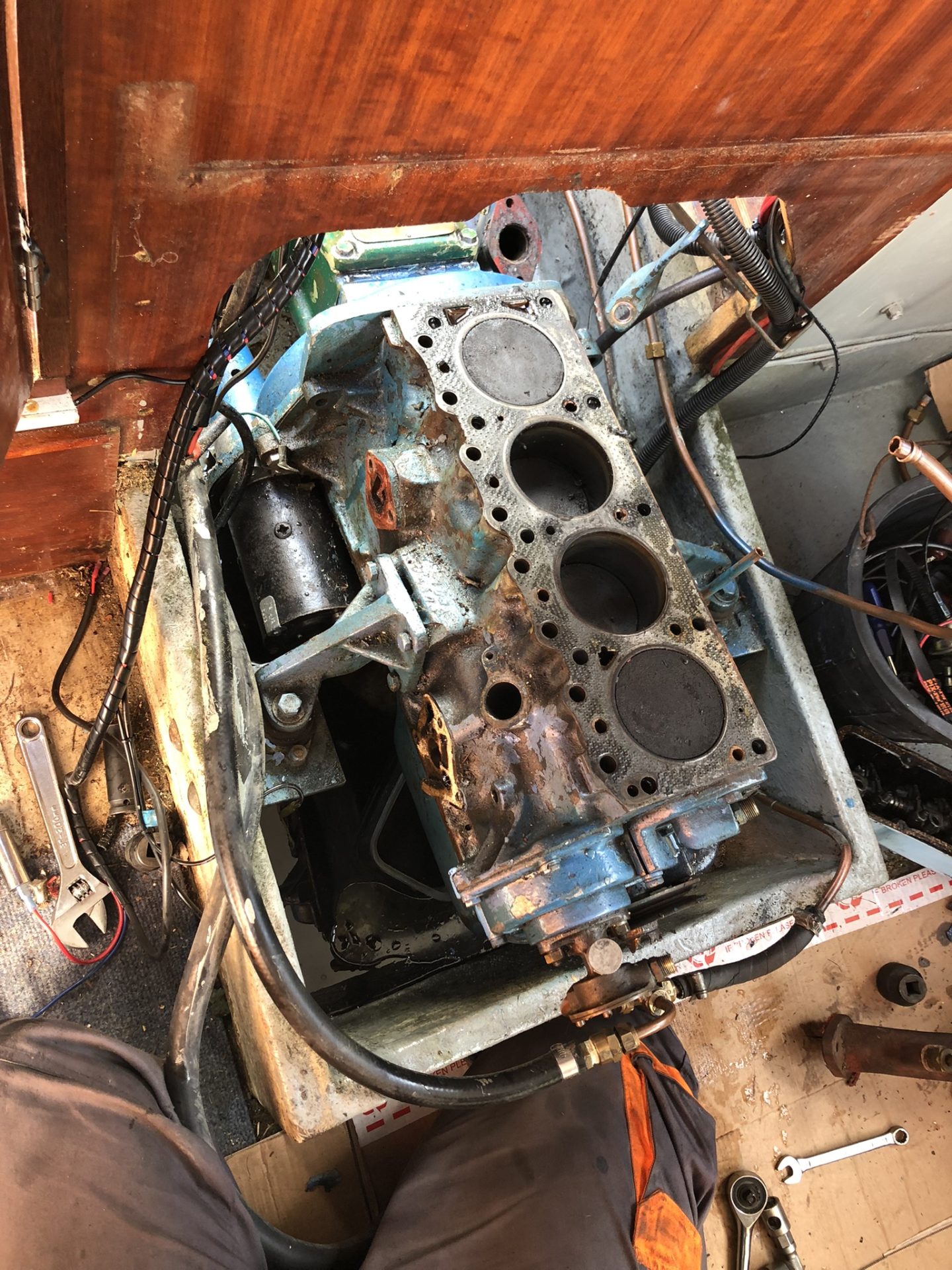

In order to replace them, the engine really needed to come out and given that a common reason for blow-by and increased crank case pressure are glazed bores and stuck or worn piston rings, I elected to take up the exceptionally kind offer of Martin Festa Bulldeath to strip the engine down to see what I was dealing with and to work out a course of action.

We ran a compression test with all the cylinders returning good pressures from 120, to 125psi. The plugs looked slightly rich, but in very good shape. As the bottom end was being torn down anyway, there was little point in doing the compression test with oil.

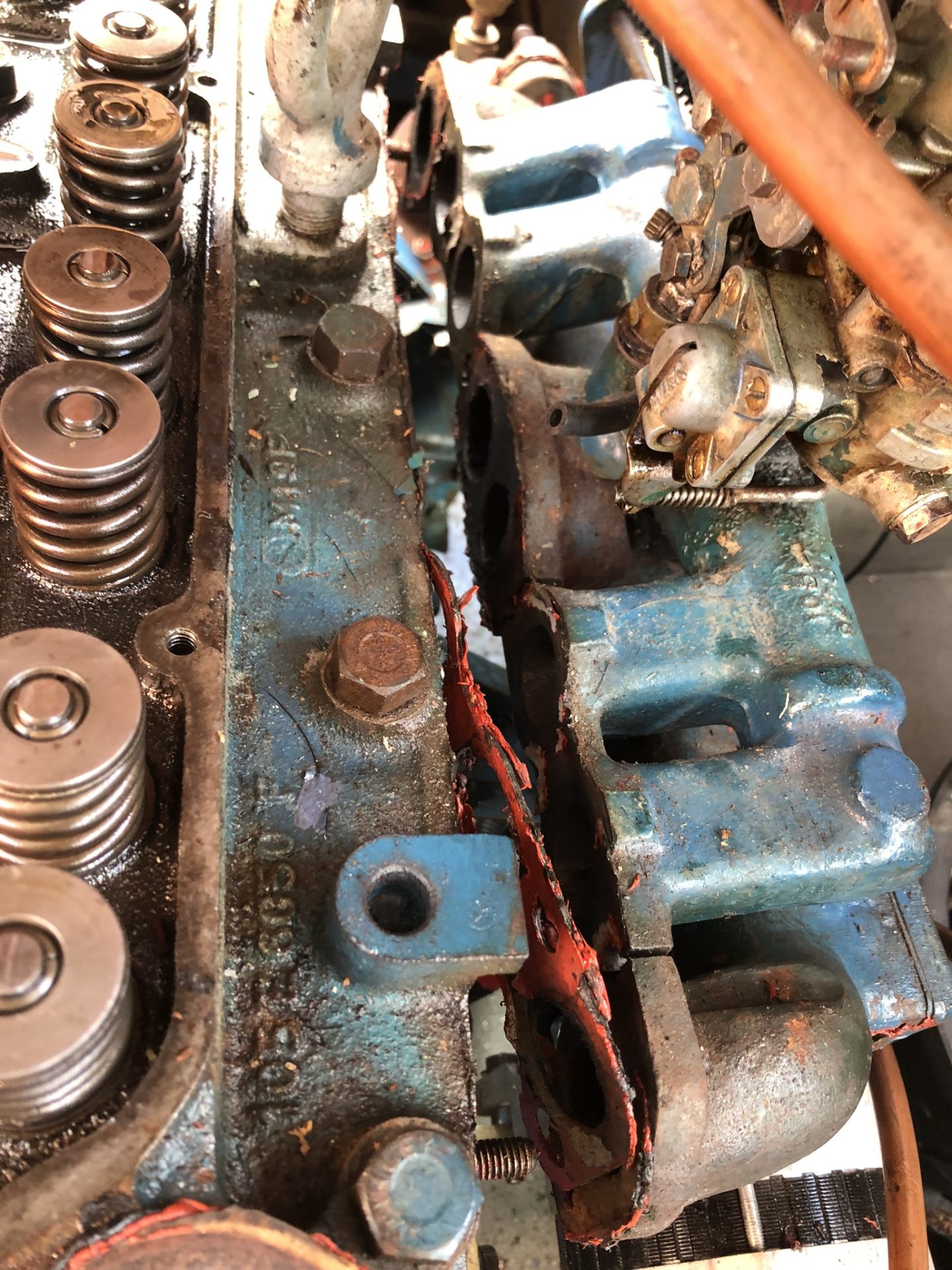

Martin set to work stripping down the engine, something he could pretty much do with his eyes shut. Then some good news. The cylinders hadn’t been messed with. The bores were very shiny and glazed with no visible crosshatching, but also no nasty scratches, lips or cracks. Pulling the pistons revealed that they were in great shape and standard size. The big end bearings were in excellent condition, in fact too good which suggests they had been fairly recently replaced, or replaced but then not used much.

The rear oil seal simply ejected it’s self but otherwise the bottom end doesn’t look like too much work is needed.

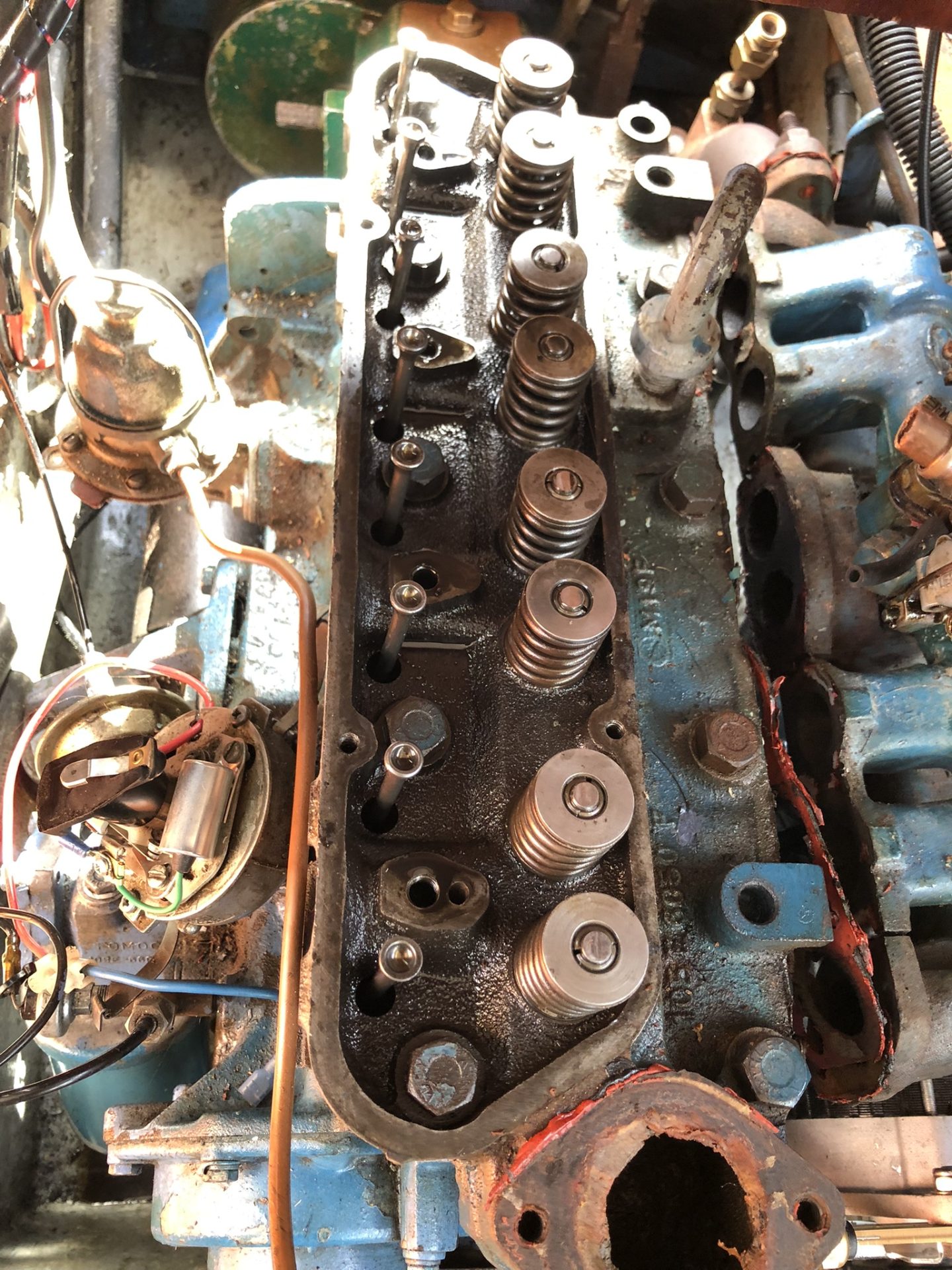

Then to the cylinder head. If the ‘breathing’ isn’t entirely coming from blow-by from the cylinders then something else was contributing. Although on quick inspection nothing looked too bad, a wiggle on the valves revealed excessive wear along with the valve stem seals having hardened to Bakerlite levels.

Cylinder 2 showed the most evidence of leakage with the valve stem showing clear wear (which you can see in a couple of the pictures)

So now I need to lightly hone the bores with a 3-pronged tool rather than one of those dingleberry tools in order to keep the bore surfaces true and give them that ‘crosshatch’. Then it’s an extremely thorough cleandown of all the parts with engine degreaser and a good spraying of WD-40 while I then get quotes for machining valve guides and supplying new valves, possibly also valve seats. As a note, I won’t be using seats intended for unleaded fuel ! The reason for this is that most car installed engines will run a lot hotter and on a raw water cooled engine, the inserts could either fall out or crack if they get too hot which many automotive engineers might not pick up on. (Edit – Following a discussion with a Ford engine specialist machine shop, they have persuaded me to go with hardened valve seats to work better and longer with unleaded fuel. As the engine doesn’t get that hot, I’m going with the expert opinion)

If the cleaning and degreasing goes well, I may give the block and head a little cosmetic colour but I’m really most interested in the engineering being sorted.

I’ll follow on from this post as I go with a little series which might end up contradicting some of my findings posted here but that’s all part of the journey.

Summary

My blow-by was a symphony of small things which under a casual description would be termed as a worn out engine. Of course that’s not true. I did have reasonable compression across all cylinders (around 120 give or take 5psi) however the bores were pretty much a mirror surface with no crosshatching to speak of (so no oil being retained in the bores).

The piston rings had gaps that were much larger than tolerance but they weren’t ‘stuck’. The bigger issue were worn valve guides across the board and exhaust valves needing replacement. Valve seats weren’t in the best shape either.

The colouration of my cylinder head gasket suggested cylinder #2 becoming a bit hot which also coincided with the exhaust valve being particularly worn. It is also likely that muddy, rusty silt in the main block waterways may have contributed to #2 cylinder complaining.

All in all, nothing had singularly failed but it proves a point that the phrase ‘runs like a sewing machine’ has no value whatsoever.