by chris

Share

Just a quick haul out, polish, antifoul and splash back in… …not likely !

The haul out was fairly trouble-free although the slipway near our berth has a very shallow incline with the tide fairly low, making the whole operation quite marginal. I’ve never seen ‘Lady’ out of the water before, having bought her on good faith (arguably a reckless thing to do but as the purchase price was under £10k, it seemed a risk worth taking). She’s been afloat for a good two years so a lift was more than due.

Lady’s bottom had a good coating of slime and a fairly even distribution of blisters the size of 50p’s. The blisters were full of water, but not osmotic in the sense the water didn’t smell of pear drops. To me this suggests the blisters were from a paint failure between an epoxy primer coat and the gelcoat which is no real surprise given that preparation isn’t a lot of fun under a boat.

As I don’t want to loss the best part of the season, I’ve scraped the bottom, bursting all the blisters and coarsely sanded the entire bottom. Following that, the bottom has been pressure washed and after a week of drying I’ll cover with an underwater epoxy primer as a barrier coat to superficially replace the gelcoat and then antifoul. It’s not a proper job, but sufficient to keep me going for a season or two, perhaps longer if I’m lucky.

I’ve made a few gelcoat repairs, particularly where I’m replacing the old corner fenders which is a tricky business considering how thin Freeman gelcoat is in places. I’m convinced this is from the factory rather than too much polishing over the years. Following on from the gel repairs, the hull was compounded and ceramic hybrid waxed. This is a bit of an experiment but in theory, if the ceramic wax holds up to the hype, I’ll only need to wash the hull and top up with product every few months rather than having to abrade the hull any further with cutting compounds and polishes.

You can see a before and after image here – On the face of it, not a huge difference but Y-10 (Oxalic acid) certainly has dealt with yellowing on the waterline.

Osmosis shuffle

Most Freemans suffer with some osmosis and White Lady is no exception. On hauling out I found a multitude of blisters around the size of a pound coin. On closer inspection, most appeared to be where a previous application of filler had failed as the liquid behind them wasn’t the thicker liquid smelling of pear drops that you would expect but rather ‘fresh’ water.

As I don’t want to miss out on much more of the season, I’ve chosen to afford a good, medium-term repair prior to antifouling. To do this I’ve ground out the failed filler which looks like International Watertite but clearly wasn’t applied as instructed with an initial primer coat. For this I used something similar to a Dremel to give me better control than using an angle grinder. A day spent under the boat with PPE and motivation left me with lots of shallow holes to fill.

I’ve chosen to use West System epoxy with a fast hardener and using fillers 407 Low Density Filler and 410 Microlight. Both of these achieve the same thing with the 407 being somewhat stronger. I happened to have some left over 407 to use up although strength is largely irrelevant when effectively filling gelcoat underwater. The 410 promises to be easier to sand to fair which is a major benefit.

Following the filling and fairing, I’ll overcoat with a single part underwater antifouling primer and then antifoul as usual. I was tempted to prime with a high-build epoxy but will leave this to another time as preparation requires all traces of old paints and antifouling to be removed which is a big job. To this end, the current combination of paints and antifoul should come away using ‘PeelAway’ when I have more time and better facilities in future.

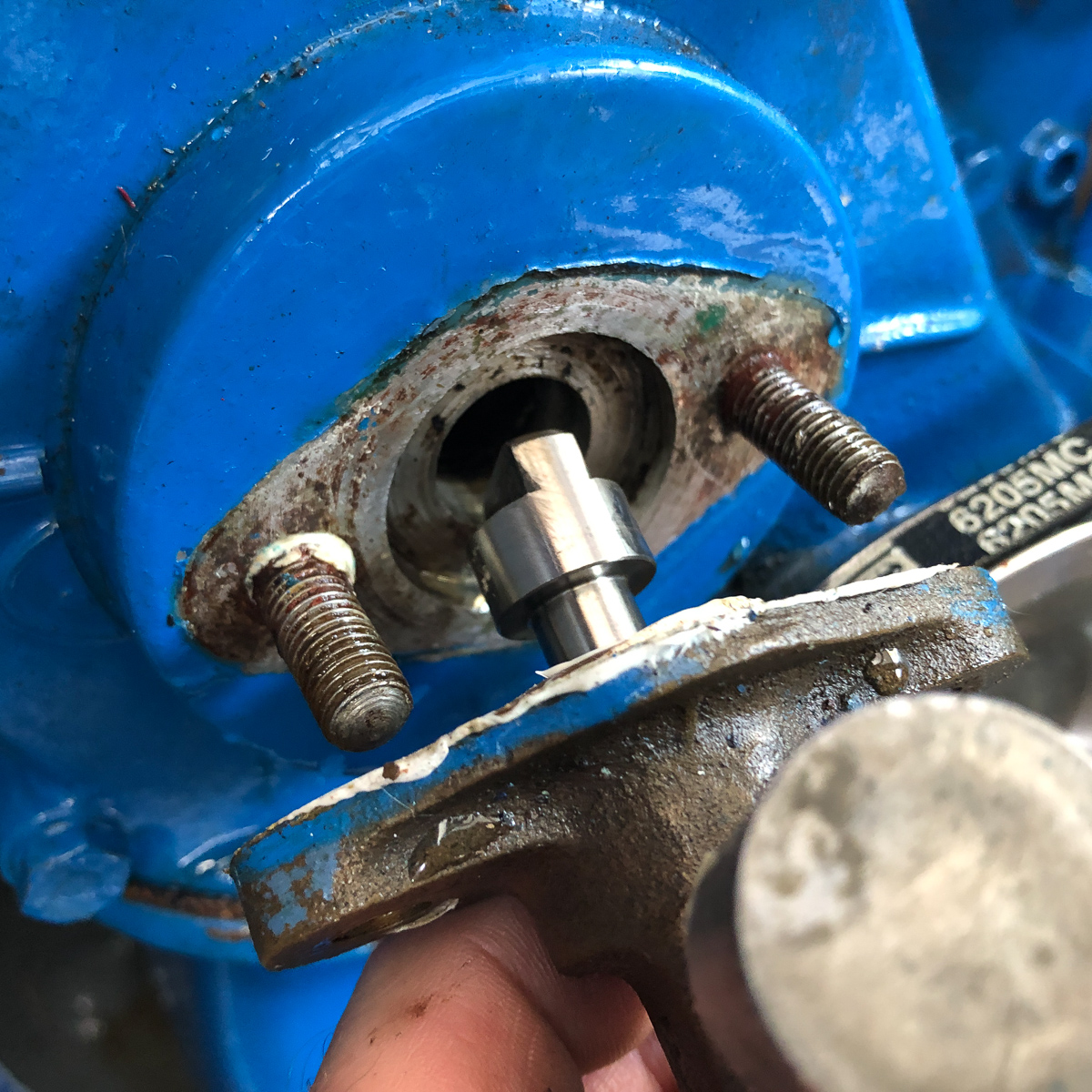

I mention this as a footnote as I don’t have any pictures but I did replace the log hose and stern gland packing while the boat was out of the water. It wasn’t easy to separate the shaft from the flange which bolts to the gearbox as the boat warps whilst on the trailer. Don’t ever try aligning your engine unless you’re afloat !